- -10%

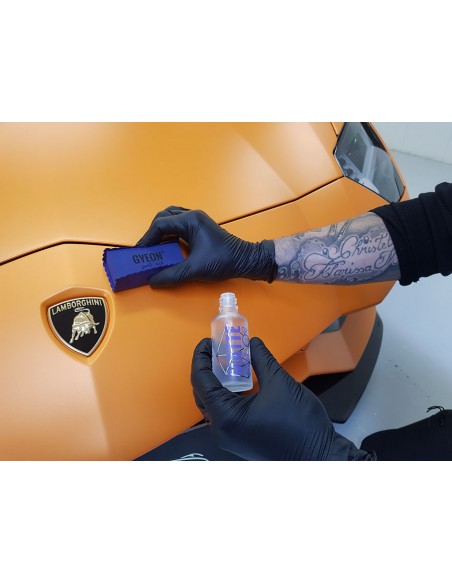

GYEON Q² Matte EVO ceramic coating

![]()

Unique ceramic coating for matte finishes.

Enhances colour without changing the finish of your matte paintwork, PPF or vinyl wrap.

Q² Matte EVO is a one layer formula, easy to apply that is highly hydrophobic and designed for maximum durability.

A major benefit of Q² Matte EVO is its neutral finish on matte or satin paints. Its silicon dioxide (SiO2) based formula has been specially designed to provide high UV and chemical protection combined with great self-cleaning properties on the very demanding structure of matte paintwork.

All EVO formulas can be applied outdoors. Ensure stable conditions, never use in direct sunlight and check the weather forecast! The coating should not get wet in the first 12 hours after application.

Q² Matte EVO coating might be used on all matte and satin-finished surfaces including paintwork, colour changing film as well as PPF or carbon fibre.

CONSUMPTION: 30-50ml/car

PH TOLERANCE: 2-11

DURABILITY: up to 24 months / 30k km

BOX CONTAINS: Q² MATTE EVO / Q²M COATING APPLICATOR / Q²M CURE MATTE 100ML / INSTRUCTION MANUAL / MAINTENANCE BOOKLET MINI / DOOR STICKERS / #GYEONIZED STICKER

You might also like